Air Bubble Film Twin Screw Extruder (3 Layer Bubble Film) Description3 layer bubble film extruder primarily takes LDPE, LLDPE or recycled materials as raw materials. Raw materials are first extruded by twin screws of main extruder at very high temperature to produce bubble films. Next these bubble films......

Description

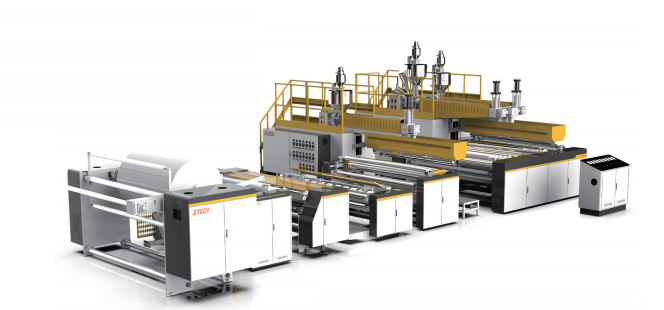

3 layer bubble film extruder primarily takes LDPE, LLDPE or recycled materials as raw materials. Raw materials are first extruded by twin screws of main extruder at very high temperature to produce bubble films. Next these bubble films are added an additional PE film by the secondary extruding system. Compared to single screw extruder, thickness of bubble layer and base layer can be controlled separately thus saving material cost. Various formulas can be used to produce bubble films of various colors. This machine features a very steady operation.

Application

3 layer bubble film is an impact-resistant, moisture-proof and shockproof chemical product suitable for packing, which is non-toxic, tasteless and has a very nice shock absorption ability. It features good impact resistance, heat resistance, moisture resistance, corrosion resistance, transparency and so on. Bubble film can be used as packing material for mechanical parts and glasses. It can also be used in the swimming pool.

.jpg)

Features

1. Our air bubble film single screw extruder has very good production capacity, with the standard speed of 30 meters per minute. This machine can be modified to have a speed up to 50 meters per minute as requested.

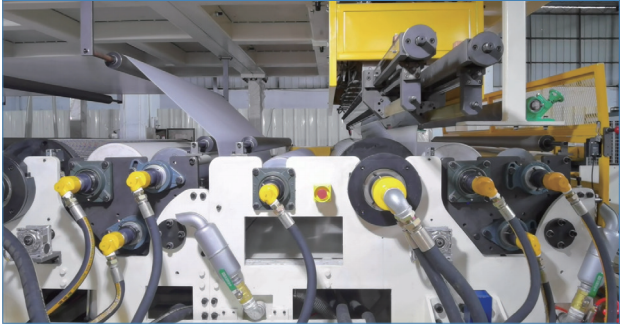

2. Our extruder has very good quality. Ztech's unique forming cylinder mold is designed with a vacuum system, with very special steel sheets to prevent wearing, and with a dual cooling system to realize a better and more uniform cooling effect. Ztech's unique T-die design is of vital importance to producing high quality bubble film. Precise T-die materials ensures that product is even in thickness, easy in operation and never leak glue. Ztech's screw design ensures that 100% recycled material is usable, that plastics melt fully to produce bubbles with better quality and even thickness.

3. Ztech's bubble film extrusion machines are very safe. Emergency stop button can stop the entire machine, including circuits, extruders and cylinder of roller. Protective barriers are installed on all important parts. All actions halt to prevent damage whenever these barriers are opened.

Technical Parameters

Model:| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1030 |

| Effective width after trimming (mm) | 1000 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 78kg/hr-140kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ55mm+Φ55mm |

| Secondary screw diameter (mm) | Φ55mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 27 |

| Power of main motor (kW) | 11KW+11KW |

| Power of secondary motor (kW) | 11 |

| Power of vacuum pump (kW) | 1.5 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 123 |

| Heating power (kW) | 80 |

| Effective power (kW) | 37 |

| Weight (kg) | 7200 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1230 |

| Effective width after trimming (mm) | 1200 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 85kg/hr-140kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ55mm+Φ55mm |

| Secondary screw diameter (mm) | Φ55mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 27 |

| Power of main motor (kW) | 11KW+11KW |

| Power of secondary motor (kW) | 11 |

| Power of vacuum pump (kW) | 1.5 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 127 |

| Heating power (kW) | 84 |

| Effective power (kW) | 38 |

| Weight (kg) | 8000 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1280 |

| Effective width after trimming (mm) | 1250 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 87kg/hr-140kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ55mm+Φ55mm |

| Secondary screw diameter (mm) | Φ55mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 27 |

| Power of main motor (kW) | 11KW+11KW |

| Power of secondary motor (kW) | 11 |

| Power of vacuum pump (kW) | 1.5 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 128 |

| Heating power (kW) | 85 |

| Effective power (kW) | 39 |

| Weight (kg) | 8200 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1530 |

| Effective width after trimming (mm) | 1500 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 115kg/hr-140kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ65mm+Φ65mm |

| Secondary screw diameter (mm) | Φ55mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 27 |

| Power of main motor (kW) | 18.5KW+18.5KW |

| Power of secondary motor (kW) | 11 |

| Power of vacuum pump (kW) | 2.2 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 160 |

| Heating power (kW) | 106 |

| Effective power (kW) | 48 |

| Weight (kg) | 8800 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1630 |

| Effective width after trimming (mm) | 1600 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 118kg/hr-185kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ65mm+Φ65mm |

| Secondary screw diameter (mm) | Φ55mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 27 |

| Power of main motor (kW) | 18.5KW+18.5KW |

| Power of secondary motor (kW) | 11 |

| Power of vacuum pump (kW) | 2.2 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 163 |

| Heating power (kW) | 108 |

| Effective power (kW) | 49 |

| Weight (kg) | 9000 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 1830 |

| Effective width after trimming (mm) | 1800 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 125kg/hr-220kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ65mm+Φ65mm |

| Secondary screw diameter (mm) | Φ65mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 28 |

| Power of main motor (kW) | 18.5KW+18.5KW |

| Power of secondary motor (kW) | 18.5 |

| Power of vacuum pump (kW) | 2.2 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 182 |

| Heating power (kW) | 120 |

| Effective power (kW) | 54 |

| Weight (kg) | 9900 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 2030 |

| Effective width after trimming (mm) | 2000 |

| Speed (m/hr) | 800m/hr-2000m/hr |

| Production Capacity (kg/hr) | 158kg/hr-248kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ75mm+Φ75mm |

| Secondary screw diameter (mm) | Φ65mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 28 |

| Power of main motor (kW) | 22KW+22KW |

| Power of secondary motor (kW) | 18.5 |

| Power of vacuum pump (kW) | 3 |

| Maximum rolling diameter (mm) | Φ1000mm (Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 210 |

| Heating power (kW) | 122 |

| Effective power (kW) | 63 |

| Weight (kg) | 10200 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 2530 |

| Effective width after trimming (mm) | 2500 |

| Speed (m/hr) | 800m/hr-1500m/hr |

| Production Capacity (kg/hr) | 180kg/hr-280kg/hr |

| Range of film thickness (g/m2) | 2 layers: 30g/sm-300g/sm 3 layers: 45g/sm-350g/sm |

| Main screw diameter (mm) | Φ80mm+Φ80mm |

| Secondary screw diameter (mm) | Φ75mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 32 |

| Power of main motor (kW) | 22KW+22KW |

| Power of secondary motor (kW) | 22 |

| Power of vacuum pump (kW) | 2.2/2.2 |

| Maximum rolling diameter (mm) | Φ1000mm (Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 242 |

| Heating power (kW) | 162 |

| Effective power (kW) | 73 |

| Weight (kg) | 12200 |

| Layer | 3 |

| Raw materials | Low density polyethylene / linear low density polyethylene / recycled material |

| Maximum width (mm) | 3030 |

| Effective width after trimming (mm) | 3000 |

| Speed (m/hr) | 800m/hr-1500m/hr |

| Production Capacity (kg/hr) | 208kg/hr-300kg/hr |

| Range of film thickness (g/m2) | 2 layers: 30g/sm-300g/sm 3 layers: 45g/sm-350g/sm |

| Main screw diameter (mm) | Φ90mm+Φ90mm |

| Secondary screw diameter (mm) | Φ80mm |

| Screw length-diameter ratio | 30 : 1 |

| Temperature control region | 34 |

| Power of main motor (kW) | 37KW+37KW |

| Power of secondary motor (kW) | 22 |

| Power of vacuum pump (kW) | 2.2/2.2 |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |

| Total power (kW) | 278 |

| Heating power (kW) | 188 |

| Effective power (kW) | 83 |

| Weight (kg) | 12800 |