As a trusted leader in bubble film machine manufacturing for over a decade, Ztech understands that selecting the right equipment is critical to your packaging efficiency and product quality. Here’s our expert guide to making an informed decision:

1. Assess Your Production Needs

Determine your output requirements (e.g., film width, bubble size, speed). A machine tailored to your daily output and material specifications ensures cost-effectiveness and avoids over investment.

2. Prioritize Core Technology

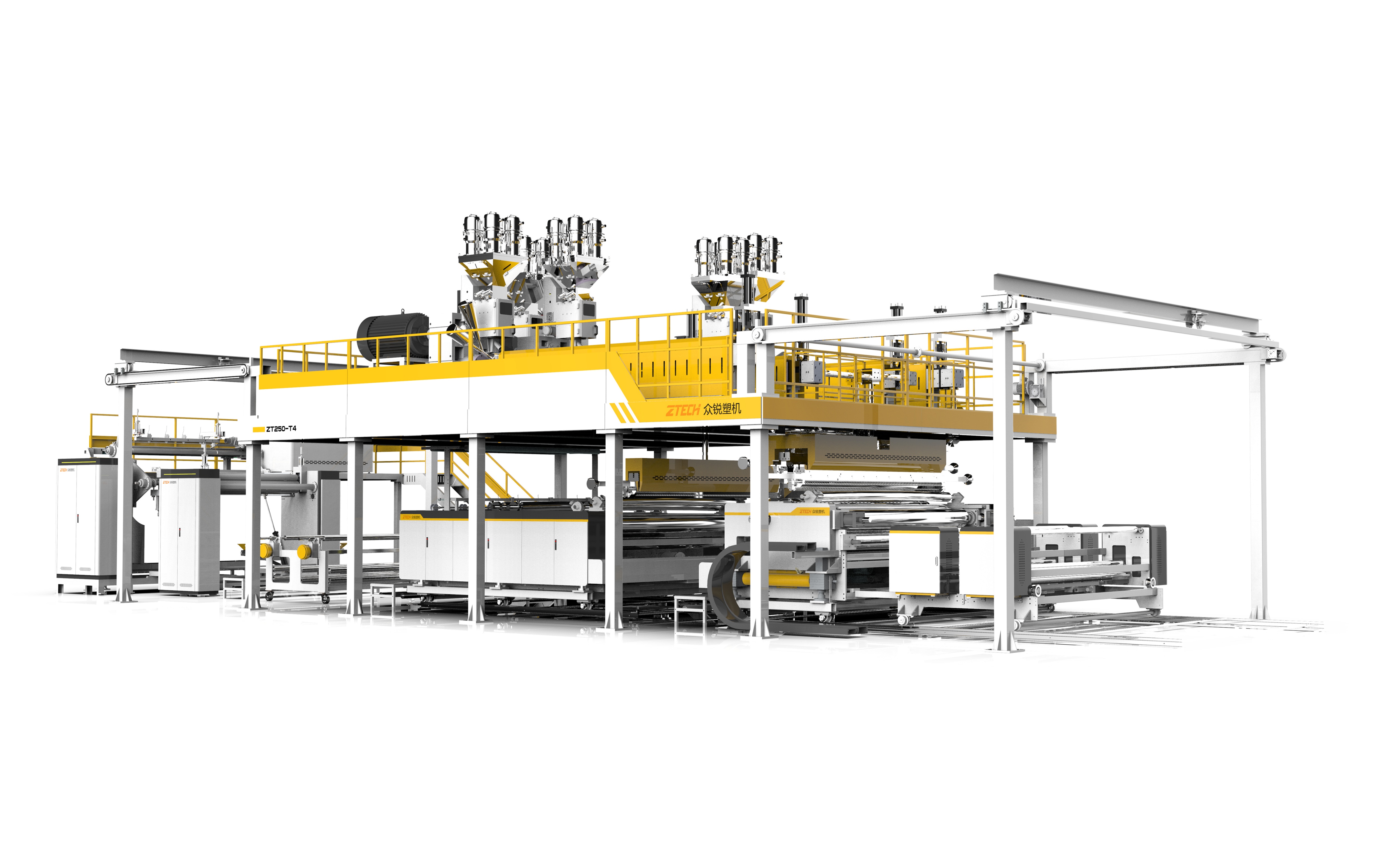

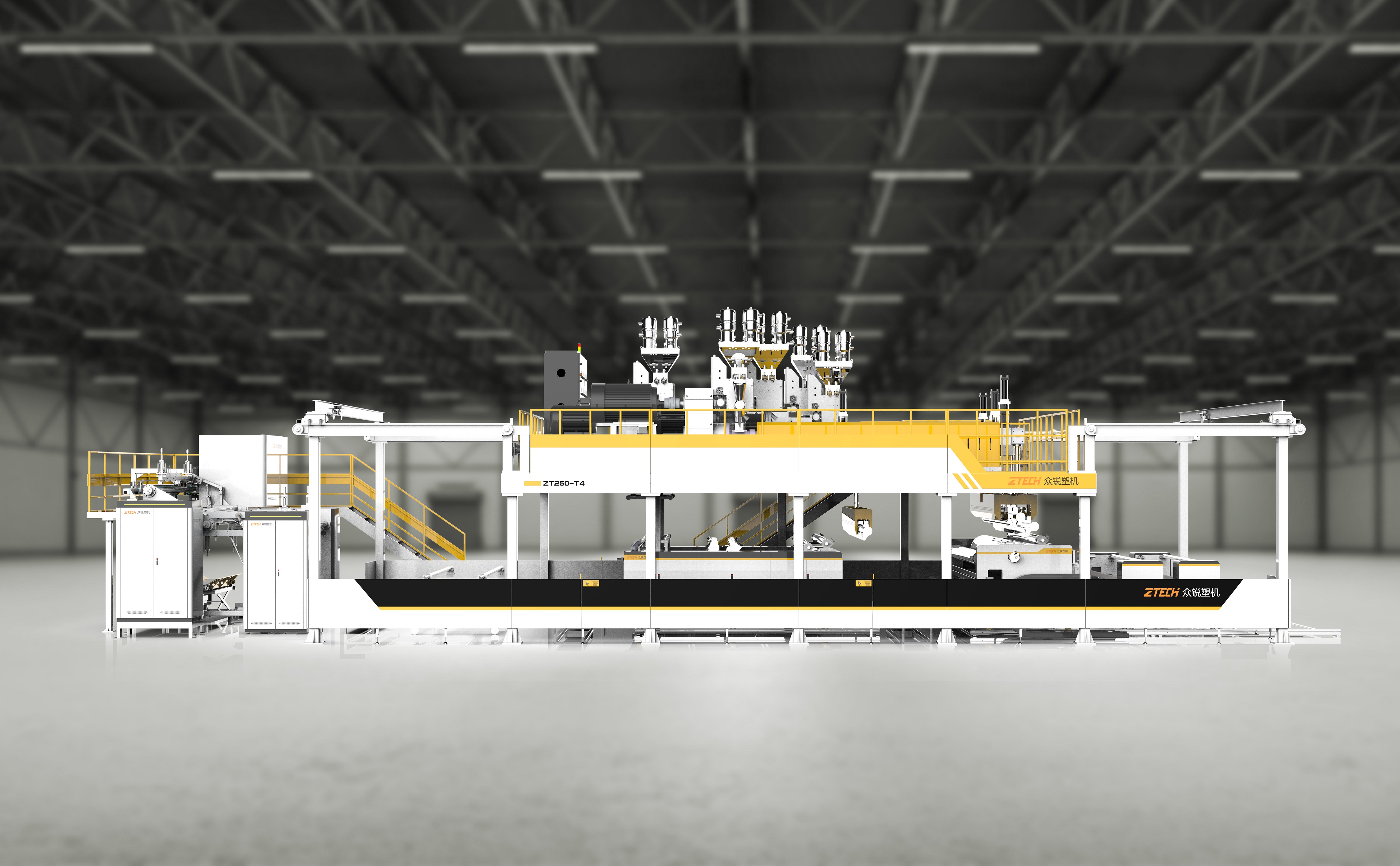

Opt for machines with advanced PLC control systems and precision extrusion modules. Ztech’s machines integrate German-engineered components, guaranteeing stable operation and consistent bubble uniformity for high-barrier packaging.

3. Energy Efficiency Matters

Modern machines with servo-driven motors and heat recovery systems can reduce energy consumption by up to 30%. Verify certifications like CE or ISO to ensure compliance with global standards.

4. Evaluate Manufacturer Expertise

Partner with proven specialists. With 10 years of R&D focus, Ztech offers customizable solutions and 24/7 technical support, backed by a global client portfolio in industries like e-commerce and electronics.

5. After-Sales Commitment

Choose suppliers offering comprehensive warranties, spare parts accessibility, and on-site training. Our team provides lifetime maintenance guidance to minimize downtime.

At Ztech, we blend innovation with reliability to deliver bubble film machines that grow with your business. Contact us today to discover how our decade of focus translates into your competitive edge.