In today's world, plastic has become an integral part of our lives, but its improper disposal has caused a severe environmental crisis. To address this issue, innovative solutions like plastic granules making machines have emerged. This article explores the concept of plastic granules making machines, their purpose, the materials they can process, and the numerous benefits they offer.

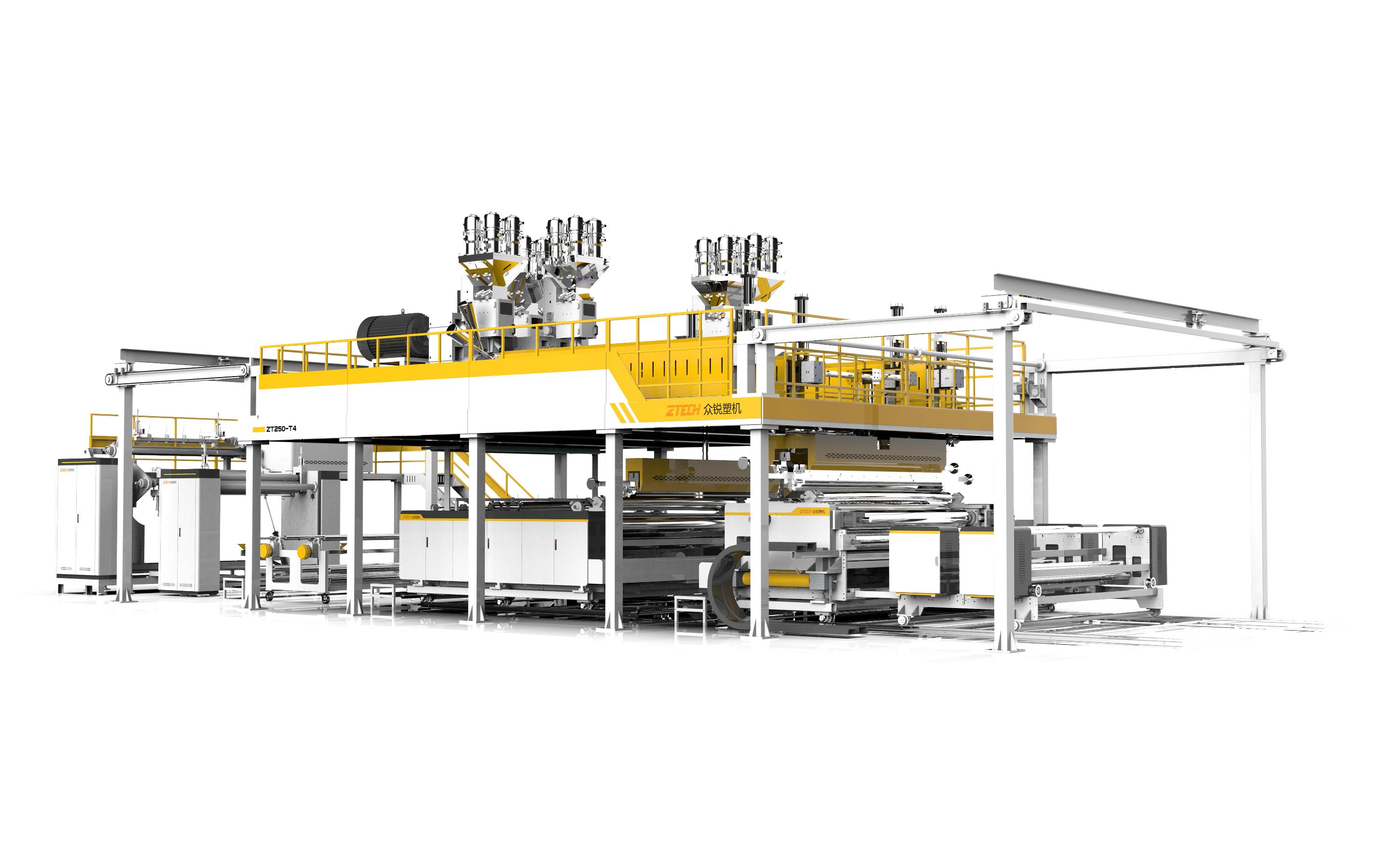

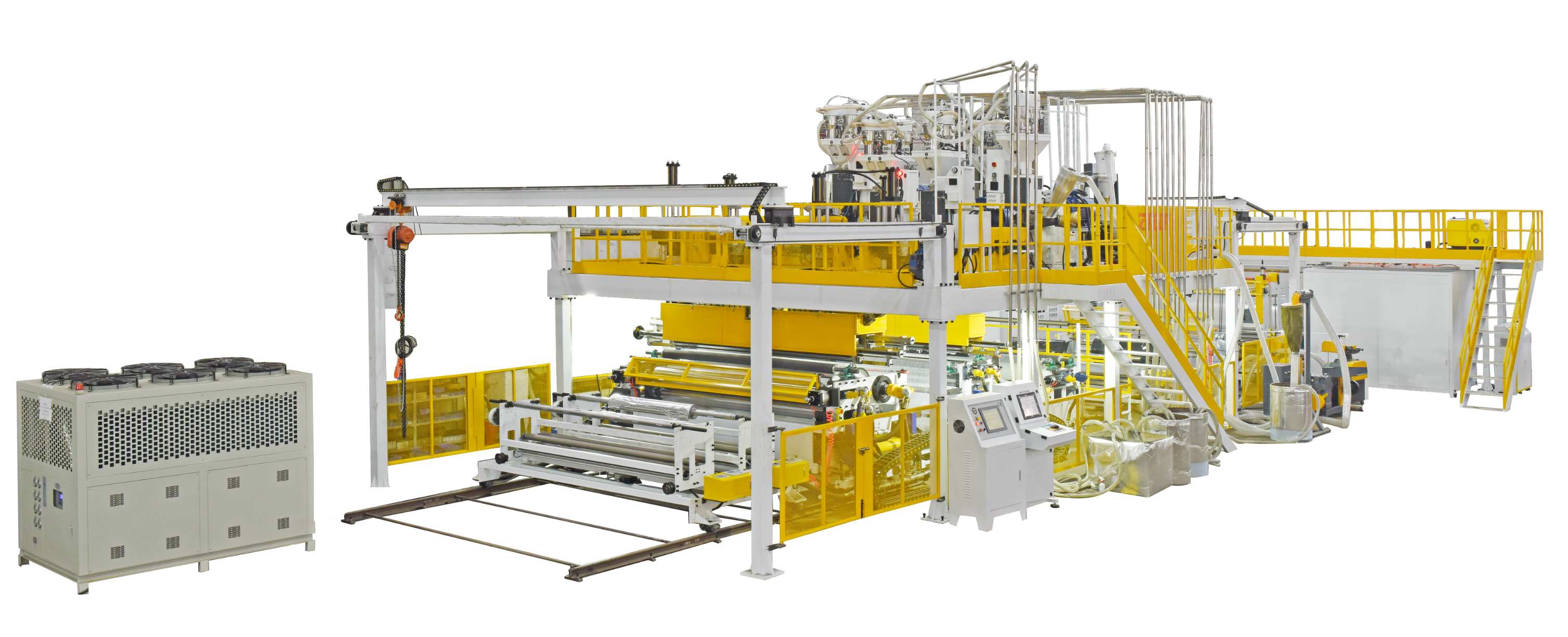

What is Plastic Granules Making Machine?

A Plastic Granules Making Machine is a piece of equipment used in the plastic manufacturing industry to convert plastic waste or raw materials into small, uniform plastic granules. These granules are typically used as raw materials for various plastic products, such as bags, containers, pipes, toys, and more.

The machine operates by melting down the plastic material and then extruding it through a die. The molten plastic is forced through the die, which has small holes or slots, resulting in the formation of cylindrical-shaped granules. These granules are cooled and solidified before being collected for further processing or packaging.

What is The Purpose of Granules?

The purpose of granules, especially in the context of plastic manufacturing, is to serve as a raw material for producing various plastic products. Plastic granules are small, uniform particles that are typically made from recycled plastic waste or virgin plastic materials. These granules have several important purposes:

●Manufacturing Efficiency

Plastic granules provide a consistent and standardized form of plastic material that is easy to handle and process in manufacturing equipment. They can be easily melted, molded, extruded, or injected into molds to create a wide range of plastic products.

●Versatility

Plastic granules can be used to produce a diverse range of plastic products, including bags, containers, bottles, packaging materials, toys, automotive parts, construction materials, and more. By using granules, manufacturers have flexibility in creating different shapes, sizes, and designs.

●Quality Control

Plastic granules undergo quality control checks during their production. This ensures that the granules have uniform properties, such as color, composition, and melt flow rate. Consistency in the raw material helps maintain product quality and performance.

●Recycling and Sustainability

Granules made from recycled plastic waste contribute to the circular economy and sustainability efforts. By converting plastic waste into granules, the recycling process becomes more efficient and reduces the reliance on virgin plastic materials. This helps in conserving natural resources and reducing environmental pollution.

●Cost-Effectiveness

Plastic granules are often more cost-effective compared to using virgin plastic materials. Recycling plastic waste into granules reduces the need for expensive extraction and production processes associated with virgin plastics. This makes the use of granules economically viable for manufacturers.

What Material Can Be Used In Plastic Granules Making Machine?

A plastic granules making machine can process a wide range of plastic materials, including:

●Polyethylene (PE)

This includes both low-density polyethylene (LDPE) and high-density polyethylene (HDPE). PE is commonly used in packaging materials, plastic bags, bottles, and various other plastic products.

●Polypropylene (PP)

PP is a versatile plastic used in packaging, automotive parts, appliances, and consumer products.

●Polyvinyl Chloride (PVC)

PVC is a widely used plastic known for its durability and resistance to chemicals. It is used in pipes, fittings, cables, flooring, and other construction materials.

●Polystyrene (PS)

PS is used in disposable food containers, packaging materials, insulation products, and consumer goods.

●Polyethylene Terephthalate (PET)

PET is commonly used in beverage bottles, food containers, polyester fibers, and packaging films.

●Polyamide (PA) or Nylon

PA is known for its strength and durability. It is used in automotive components, textiles, electrical parts, and engineering applications.

●Acrylonitrile Butadiene Styrene (ABS)

ABS is a rigid plastic used in automotive parts, electronic housings, toys, and appliances.

●Polycarbonate (PC)

PC is a transparent and impact-resistant plastic used in safety glasses, CDs, electronics, and automotive components.

●Polyethylene Terephthalate Glycol (PETG)

PETG is a variant of PET and is commonly used in medical applications, such as packaging for pharmaceuticals and medical devices.

What Are the Benefits of Using A Plastic Granules Making Machine?

Using a plastic granules making machine offers several benefits in the plastic manufacturing industry. Here are some key advantages:

●Efficient Recycling

Plastic granules making machines enable the efficient recycling of plastic waste. By converting plastic waste into granules, the machines contribute to the circular economy and sustainability efforts. This helps reduce the amount of plastic waste that ends up in landfills or oceans.

●Cost-Effectiveness

Using plastic granules as raw materials can be more cost-effective compared to using virgin plastic materials. Recycling plastic waste into granules reduces the need for expensive extraction and production processes associated with virgin plastics. This cost savings can benefit manufacturers and consumers alike.

●Consistent Quality

Plastic granules offer a consistent and standardized form of raw material. The granules undergo quality control checks during production to ensure uniform properties, such as color, composition, and melt flow rate. This consistency helps manufacturers maintain product quality and performance.

●Versatility in Production

Plastic granules can be used to manufacture a wide range of plastic products. The granules can be easily melted, molded, extruded, or injected into molds, providing flexibility in creating different shapes, sizes, and designs. Manufacturers can tailor their production processes to meet specific product requirements.

●Customization and Innovation

Plastic granules making machines allow manufacturers to experiment with different types of plastic materials and additives. This opens up opportunities for customization and innovation in the development of new plastic products with enhanced properties or specific characteristics.

●Reduced Environmental Impact

By recycling plastic waste and using granules, the plastic manufacturing process can contribute to reducing environmental pollution. Recycling plastic reduces the consumption of natural resources and energy required for virgin plastic production. It also helps mitigate the negative environmental impacts associated with plastic waste disposal.

●Resource Conservation

Using plastic granules reduces the demand for virgin plastic materials, which helps conserve natural resources such as crude oil and natural gas. By promoting resource conservation, plastic granules making machines support sustainable practices and contribute to a more environmentally responsible manufacturing industry.

Conclusion

Plastic granules making machines have emerged as an effective solution to the growing plastic waste problem. By transforming plastic waste into reusable granules, these machines not only contribute to environmental conservation but also offer economic opportunities and resource efficiency. The adoption of such machines is a step towards building a sustainable future, where plastic waste can be repurposed into valuable resources, promoting a circular economy.