Plastic pollution has become a pressing environmental issue, threatening ecosystems and human health. However, advancements in technology have brought about a solution in the form of plastic recycling machines. These machines play a vital role in diverting plastic waste from landfills and transforming it into valuable resources.

What is Plastic Recycling Machine?

A plastic recycling machine is a device or system designed to process and transform plastic waste into reusable materials. It typically consists of various components and processes that work together to sort, clean, and transform different types of plastic waste into new products or raw materials for manufacturing.

How Does Plastic Recycling Machine Work?

The specific operations and technologies used in a plastic recycling machine may vary depending on the scale and complexity of the system. However, common processes involved in plastic recycling machines include:

●Sorting

Plastic waste is often mixed with other materials, such as paper or metal. Sorting mechanisms separate different types of plastics based on their resin codes or physical properties.

●Shredding or Granulating

The plastic waste is reduced in size through shredding or granulating processes. Shredders or granulators break down the plastic into smaller pieces, increasing its surface area for further processing.

●Cleaning

The shredded plastic is thoroughly cleaned to remove impurities, such as dirt, debris, labels, or adhesives. This step often involves washing, rinsing, and sometimes employing specialized cleaning methods.

●Melting and Extrusion

The cleaned plastic is melted using heat and converted into a molten state. The molten plastic is then extruded through a die, forming strands or pellets of consistent size and shape.

●Pelletizing or Compounding

The extruded plastic strands or pellets are cooled and cut into uniform lengths. Depending on the desired end product, the plastic may be pelletized for later use or compounded with additives to enhance its properties.

●Manufacturing or Reuse

The resulting plastic pellets or compounds can be used as raw materials in various manufacturing processes to produce new plastic products. Alternatively, they can be used as additives in existing plastic formulations, reducing the need for virgin plastic.

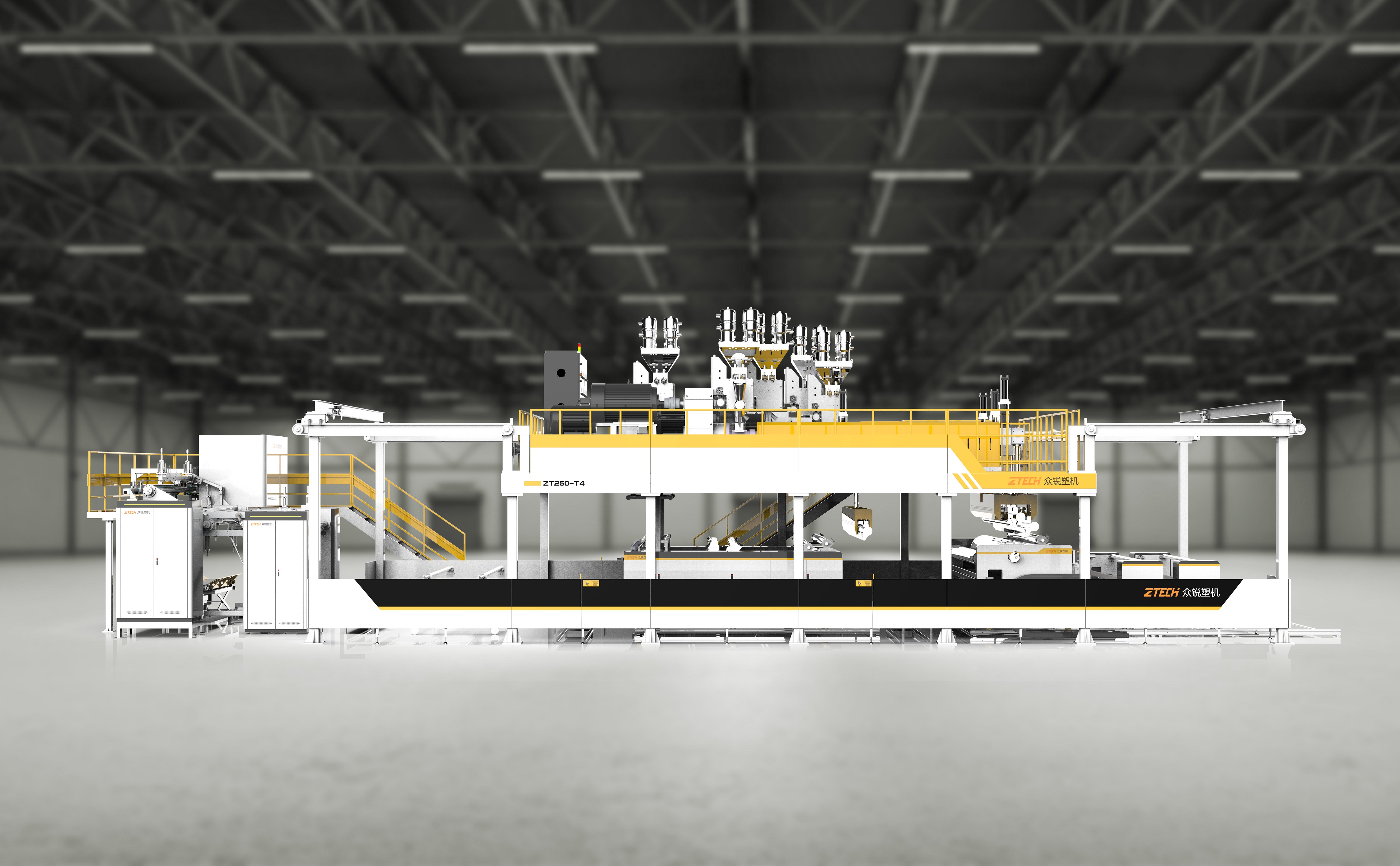

Recycling Plastic Granules Production Line

What Are The Benefits of Plastic Recycling Machine?

Plastic recycling machines offer several benefits, both environmental and economic, in the context of plastic waste management. Here are some key advantages:

●Reduction of plastic waste

Plastic recycling machines help divert plastic waste from landfills and the environment. By processing and transforming plastic waste into reusable materials, these machines contribute to reducing the amount of plastic that ends up in oceans, rivers, and natural habitats.

●Conservation of resources

Plastic recycling machines enable the recovery and reuse of valuable resources contained in plastic waste. Instead of relying solely on virgin plastic production, recycling machines help conserve energy, water, and raw materials, such as petroleum or natural gas, that are used in the production of plastics.

●Energy savings

Manufacturing plastic from recycled materials requires less energy compared to producing plastic from scratch. Plastic recycling machines contribute to energy savings by eliminating or reducing the need for energy-intensive processes involved in virgin plastic production, such as extraction and refining of fossil fuels.

●Reduction of greenhouse gas emissions

The production of plastic from virgin materials releases greenhouse gases into the atmosphere. Recycling plastic waste through machines helps reduce these emissions by decreasing the demand for virgin plastic production. Additionally, recycling can prevent the release of methane, a potent greenhouse gas, which may be generated when plastic waste decomposes in landfills.

●Job creation and economic opportunities

The establishment and operation of plastic recycling facilities create employment opportunities, contributing to local economies. Recycling machines can be part of a larger recycling infrastructure, supporting a range of jobs in collection, sorting, processing, and manufacturing sectors associated with recycling operations.

Water Ring Plastic Recycling Machine

●Promotion of circular economy

Plastic recycling machines play a crucial role in promoting a circular economy, where materials are reused and kept in circulation for as long as possible. By transforming plastic waste into reusable materials, these machines help close the loop and reduce the reliance on finite resources, fostering a more sustainable and efficient economic model.

It is important to note that the effectiveness and benefits of plastic recycling machines depend on various factors, including proper waste management infrastructure, public awareness and participation, and supportive policies and regulations. Collaboration between governments, industries, and individuals is key to maximizing the benefits of plastic recycling machines and achieving a more sustainable approach to plastic waste management.

Conclusion

Plastic recycling machine is a cost-effect and environmental friendly machine. In the current industrial era, it is very important to make good use of the plasyic recycling machine. Collaboration between governments, industries, and individuals is key to maximizing the benefits of plastic recycling machines and achieving a more sustainable approach to plastic waste management.