Welcome to the guide on maintaining your Ztech EPE foam laminating machine. Proper maintenance is crucial to ensure the longevity and efficient performance of your laminating machine.

By following the recommended maintenance procedures, you can avoid costly repairs, reduce downtime, and achieve consistent, high-quality laminations. Let's delve into the essential steps to keep your EPE foam laminating machine in excellent condition.

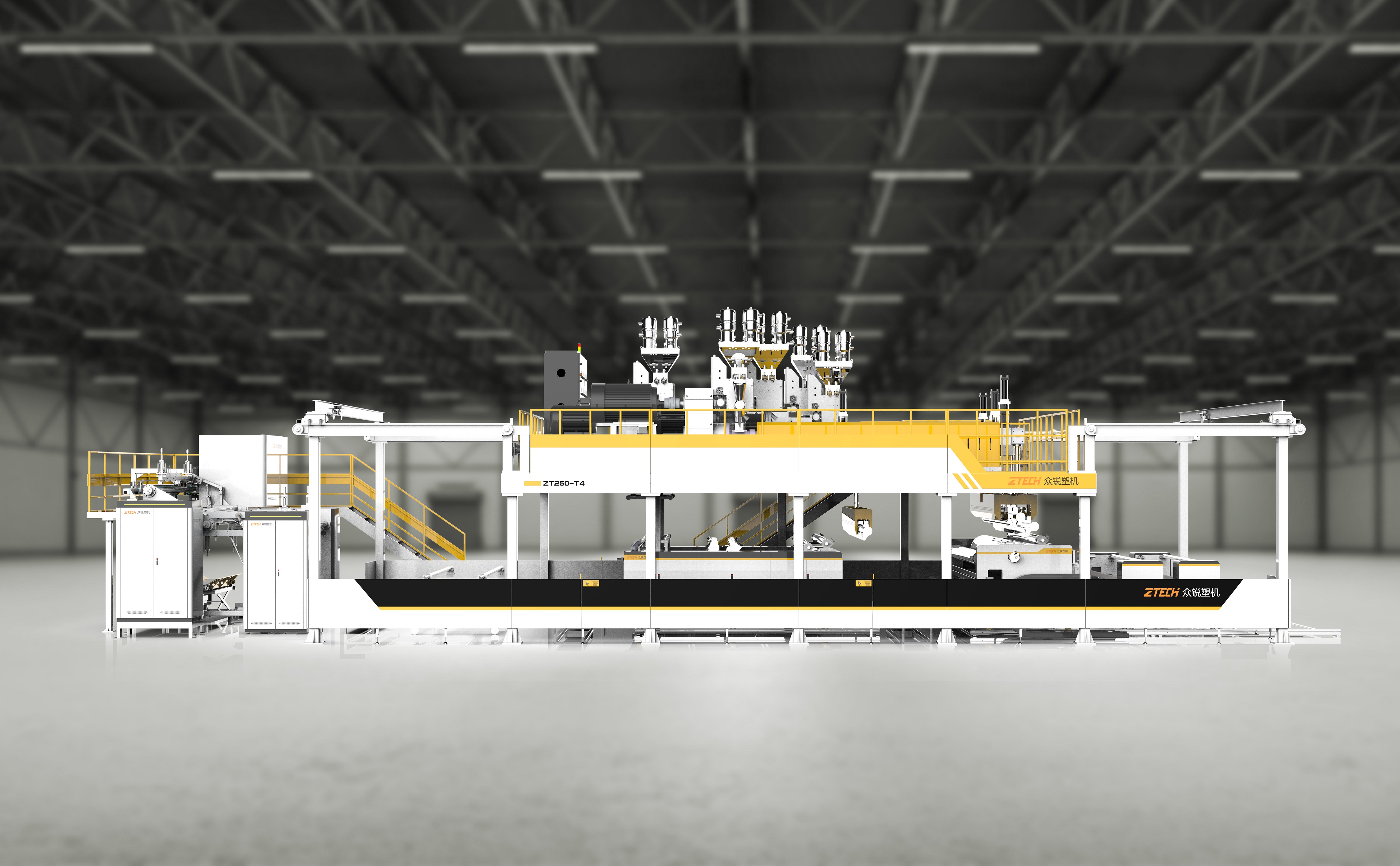

What are the Features of Ztech EPE Foam Laminating Machine

Before we begin, it's essential to understand the key components and features of your Ztech EPE foam laminating machine. This machine plays a vital role in the lamination process, where it bonds different layers of foam materials together, resulting in superior packaging solutions.

The Ztech EPE foam laminating machine typically consists of rollers, a heating system, pneumatic components, and advanced software for precise control over the lamination process. Understanding its design and functionality will help you comprehend the significance of proper maintenance.

Importance of Regular Maintenance

Regular maintenance is not only essential for extending the machine's lifespan but also for optimizing its performance. Neglecting maintenance can lead to several issues, including decreased productivity, frequent breakdowns, and compromised product quality. Moreover, improper maintenance may pose safety risks to machine operators.

By investing time and effort in maintaining your Ztech EPE foam laminating machine, you ensure that it continues to operate smoothly and efficiently, resulting in better overall productivity and cost-effectiveness.

Air Bubble Film Lamination Machine

Recommended Maintenance Schedule

To keep your EPE foam laminating machine in top-notch condition, it is vital to follow a structured maintenance schedule. Here's a breakdown of the maintenance tasks you should perform regularly:

Daily Maintenance Procedures

●Cleanliness and Dust Removal:

Wipe down the machine's surfaces, rollers, and any exposed parts to remove dust and debris.

Use appropriate cleaning agents and non-abrasive materials to avoid damage.

●Lubrication:

Apply the recommended lubricants to designated points to reduce friction and prevent premature wear of moving parts.

Weekly Maintenance Procedures

●Roller Inspection:

Check the condition of the rollers for signs of damage or wear.

Adjust or replace rollers as needed to maintain optimal laminating performance.

●Belt Tension Check:

Ensure the belts are properly tensioned to avoid slippage during operation.

Adjust the tension as required to maintain smooth and precise lamination.

Monthly Maintenance Procedures

●Heating System Calibration:

Calibrate the heating system to ensure consistent and accurate laminating temperatures.

This step is vital for achieving high-quality laminations and preventing potential bonding issues.

●Pneumatic System Check:

Examine and maintain the pneumatic components to ensure they function correctly.

Address any leaks or malfunctions promptly to avoid disruptions in the laminating process.

Yearly Maintenance Procedures

●Major Component Inspection:

Conduct a thorough inspection of critical components, such as motors, bearings, and electrical connections.

Seek professional assistance for complex inspections and repairs to ensure the machine's longevity.

●Software and Firmware Updates:

Keep the machine's software and firmware up to date to benefit from the latest improvements and bug fixes.

This ensures that your machine operates at its best and remains compatible with evolving technologies.

Troubleshooting Common Issues

Even with regular maintenance, occasional issues may arise. Here are some common problems you might encounter and their corresponding troubleshooting steps:

●Uneven Lamination:

Check for any misaligned rollers and adjust them as needed.

Ensure that the foam materials are loaded correctly to maintain uniform lamination.

●Adhesive Problems:

Verify the temperature settings and ensure the heating system is calibrated properly.

Use appropriate adhesive materials and check their expiration dates.

●Abnormal Noises:

Investigate the source of the noise, and if necessary, inspect and lubricate moving parts.

Seek professional assistance if the issue persists.

Safety Precautions

Safety should always be a priority during machine maintenance. Here are some essential safety measures to follow:

Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when performing maintenance tasks.

Power off the machine and disconnect it from the power source before starting any maintenance procedures.

Avoid wearing loose clothing or accessories that could get entangled in the machine's moving parts.

Conclusion

Maintaining your Ztech EPE foam laminating machine is essential for its optimal performance and longevity. By adhering to the recommended maintenance schedule and safety precautions, you can ensure that your machine continues to produce high-quality laminations efficiently.

Regular maintenance not only saves you from potential breakdowns and costly repairs but also enhances overall productivity and the lifespan of your EPE foam laminating machine. Invest in maintenance now to reap the benefits for years to come.