In today's environmentally conscious world, the need for effective plastic recycling solutions has become paramount. Among the various recycling technologies available, the water ring plastic recycling machine stands out as a highly efficient and versatile option.

In this post, the author would recommend you the water ring plastic recycling machine which is a good recycling option for plastic.

What is Water Ring Plastic Recycling Machine?

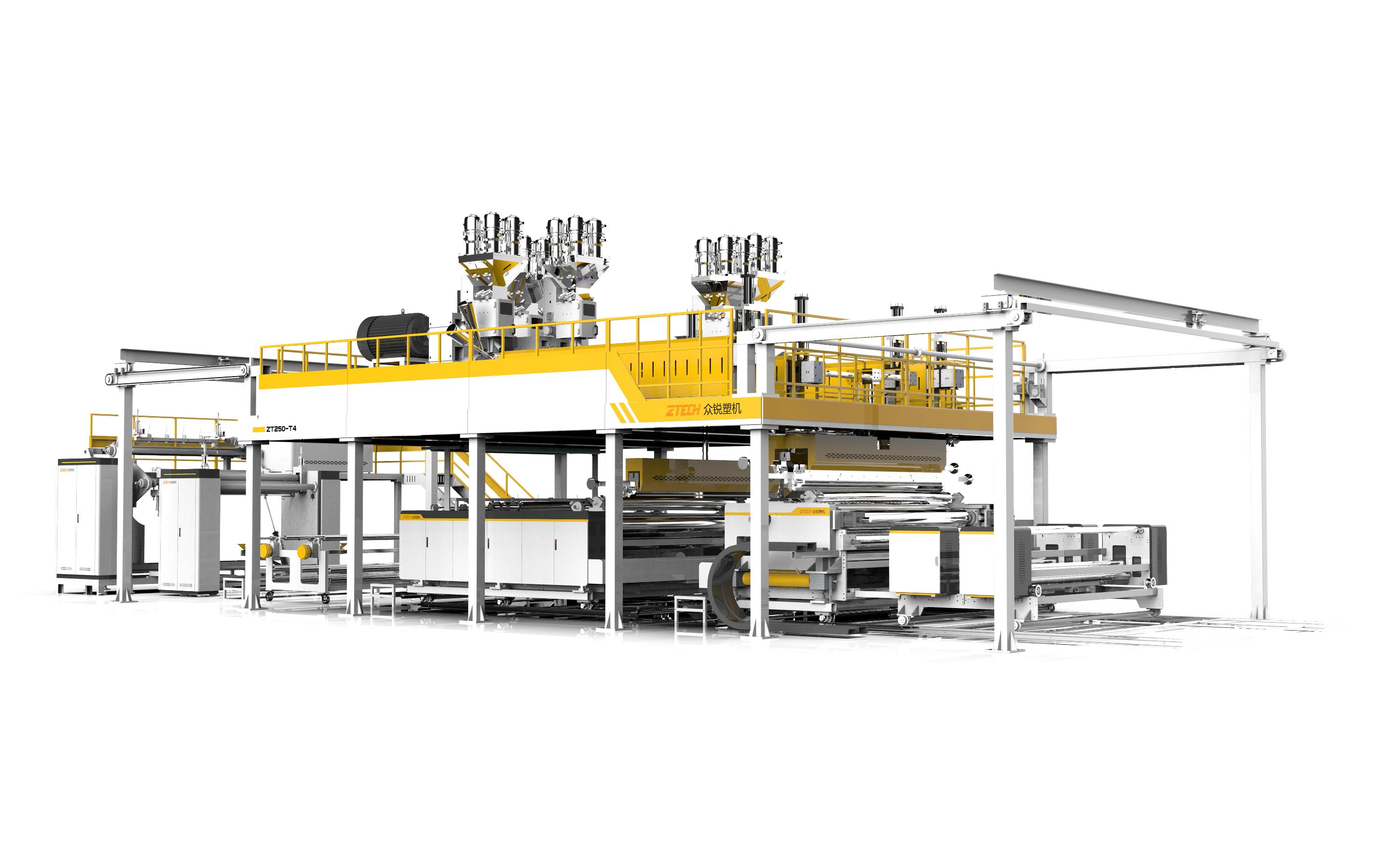

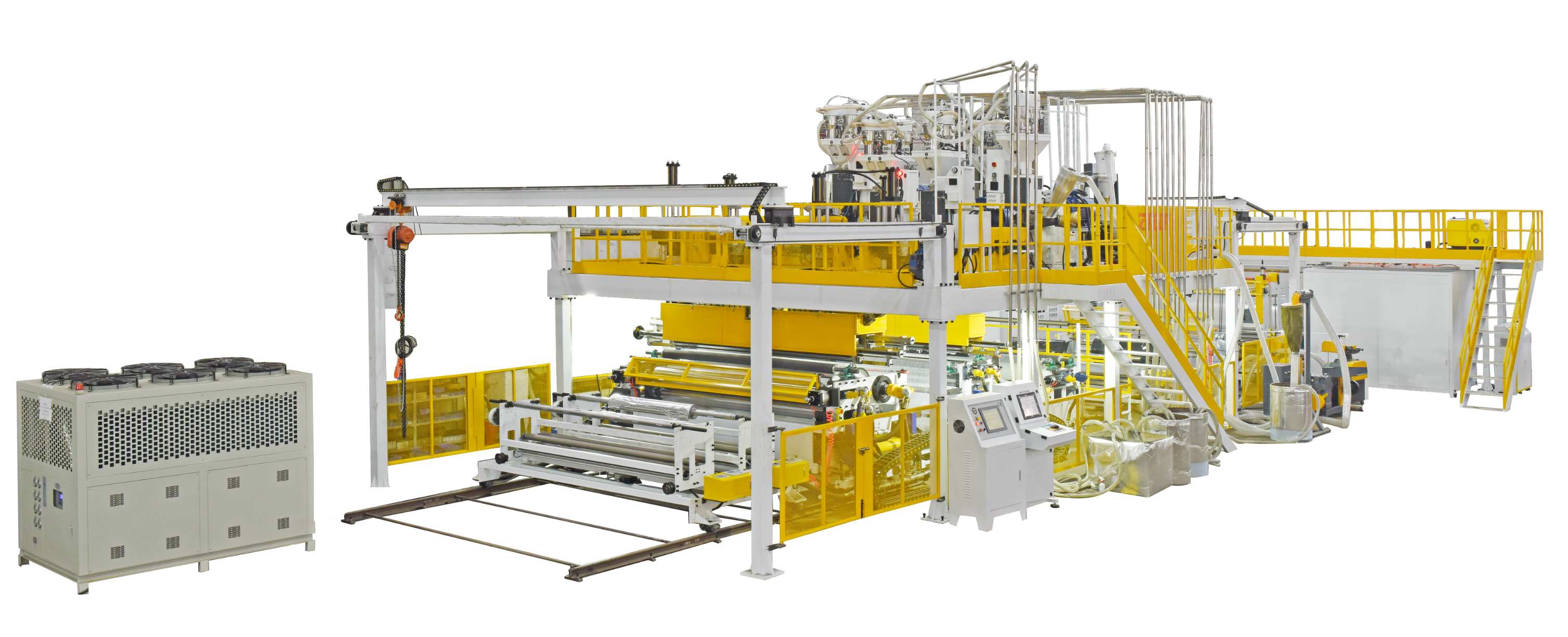

The water ring plastic recycling machine is the hot sell product in Ztech. This water ring plastic recycling machine is designed to recycle inline trims, start-up scrap, loose scrap, and reels. It can recycle various materials such as MDPE, LDPE, LLDPE, and PP.

How Does A Plastic Recycling Machine Work?

This recycling process is mainly divided into multiple procedures ---- collection and sorting, shredding, washing and cleaning, melting and extrusion, filtering and pelletizing, and further processing.

Step 1: Collection and Sorting

Plastic waste is collected from various sources, such as households, industries, or recycling centers. The waste is then sorted based on its type and composition. This sorting step is important because different types of plastic may require different recycling processes.

Step 2: Shredding

The sorted plastic waste is fed into a shredder, which mechanically cuts or shreds the plastic into smaller pieces. Shredding increases the surface area of the plastic, making it easier to handle in subsequent steps.

Step 3: Washing and Cleaning

The shredded plastic pieces are typically washed to remove any contaminants, such as dirt, debris, or residues. This is usually done by immersing the plastic in a water bath or using a washing mechanism that agitates the plastic pieces. Sometimes, chemicals or detergents may be added to help remove stubborn contaminants.

Step 4: Melting and Extrusion

After cleaning, the plastic pieces are dried and then melted down. The melted plastic is passed through an extruder, which is a machine that pushes the molten plastic through a die to create a continuous shape, such as plastic pellets or a plastic sheet. The extrusion process helps in transforming the plastic into a manageable form for further processing.

Step 5: Filtering and Pelletizing

In some cases, the molten plastic may be passed through filters to remove any remaining impurities or contaminants. Then, the plastic is typically cooled and cut into small pellets using a pelletizer. These pellets can be used as raw materials for manufacturing new plastic products.

Step 6: Further Processing

Depending on the desired outcome, the plastic pellets may undergo additional processing steps. For example, they can be melted and molded into new plastic products, mixed with other additives to enhance their properties, or used as a blend with virgin plastic for specific applications.

Water Ring Plastic Recycling Machine

What Are the Features of Water Ring Plastic Recycling Machine?

Driven by the concept of being environmentally friendly, we design an excellent plastic recycling machine. The water ring plastic recycling machine is one of our proud products. Here are the features of it.

●Designed for clean, dry scrap

The machine is specifically engineered to operate efficiently with clean and dry scrap materials, ensuring optimal performance.

●Easy access for cleaning and maintenance

The Water Ring Plastic Recycling Machine provides convenient access for easy cleaning and maintenance, simplifying the upkeep process.

●Long-lasting cutters

The slow-speed shredder rotor of the machine is equipped with four cutting edges, promoting longevity and durability, which ultimately reduces the need for frequent replacements.

●Reliable and dust-free operation

The machine is engineered to deliver reliable performance while ensuring a dust-free environment, enhancing operational efficiency and maintaining a clean workspace.

●Wide compatibility

The Water Ring Plastic Recycling Machine caters to a broad range of film widths, material types, and gauges, making it versatile and suitable for various recycling requirements.

●Simple operation

The machine's operation is designed to be straightforward, minimizing complexity and facilitating ease of use.

●Efficient use of floor space and energy

The machine is engineered to occupy minimal floor space, optimizing the utilization of available area. Additionally, it boasts energy-efficient operation, helping to reduce energy costs.

Conclusion

All in all, when you invest the water ring plastic recyclying machine, you would find it can play a crucial role in the sustainable management of plastic waste. With their versatility, high output capacity, and energy efficiency, water ring plastic recycling machines are undoubtedly a valuable asset in the quest for a greener and more sustainable future.