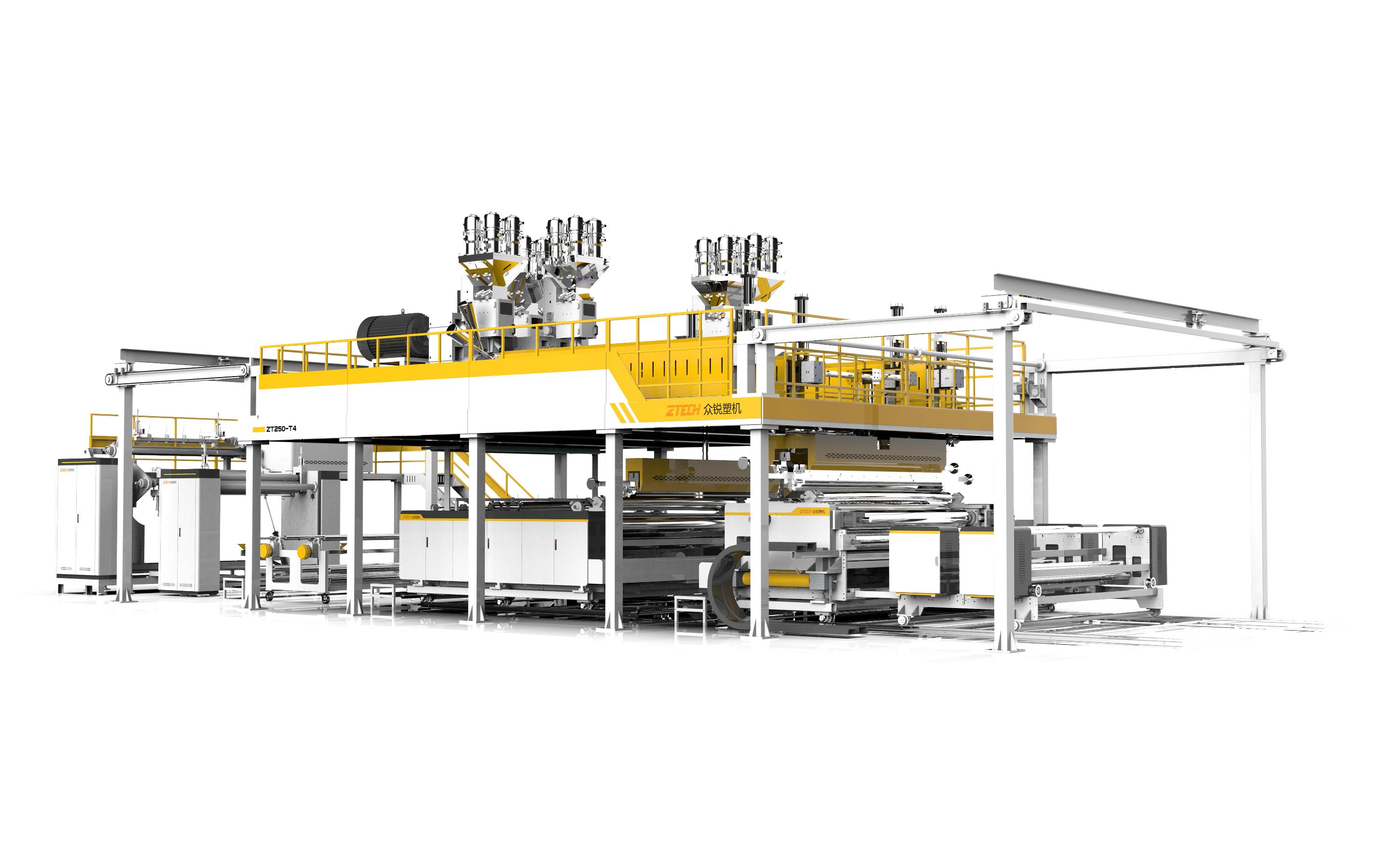

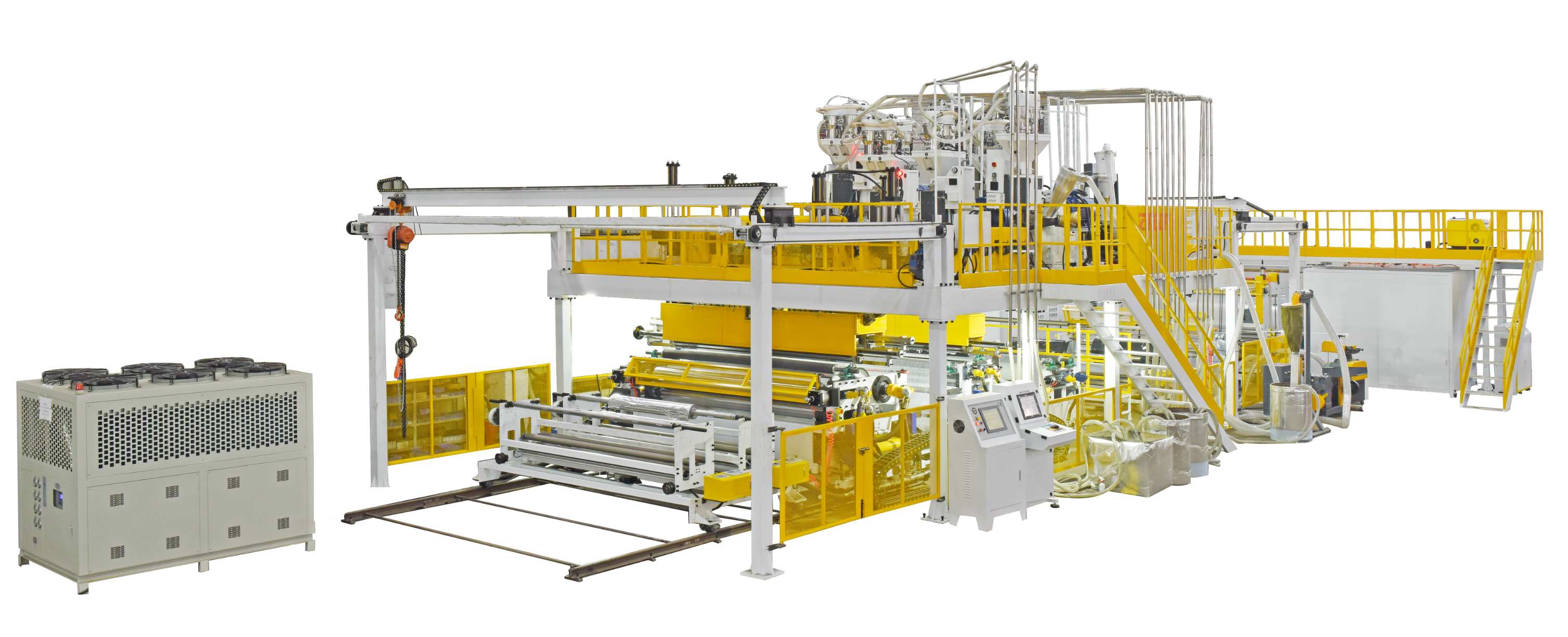

Air bubble film machines, also known as air bubble wrap machines, are versatile and efficient devices used for producing air-filled bubble wraps. These machines have become an essential tool in various industries, such as packaging, shipping, and electronics, where protecting fragile items during transit is crucial.

Today, allows to author give a brief introduction to the air bubble film machines.

Are Air Bubble Film Machines Easy to Operate And Maintain?

The ease of operating and maintaining machines can vary depending on the specific machine and its complexity. Some machines are designed to be user-friendly and intuitive, making them relatively easy to operate. They may have clear instructions, user-friendly interfaces, and require minimal training to get started. Most of Ztech’s air bubble film machines are user-friendly because they have a simple and clean operation system.

On the other hand, complex or specialized machines may require more expertise and training to operate effectively. They may have intricate controls, require specific knowledge or certifications, or demand a higher level of technical skill. In such cases, operators may need thorough training or certification programs to ensure safe and efficient operation.

Maintenance requirements also vary depending on the machine. Some machines may require regular cleaning, lubrication, or minor adjustments, which can be easily done by the operators themselves. Other machines may need more extensive maintenance, such as regular inspections, component replacements, or calibration, which could involve specialized technicians or service providers.

What is The Production Capacity of A Typical Air Bubble Film Machine?

The production capacity of a typical air bubble film machine can vary depending on several factors, including the machine's design, specifications, and the operational settings chosen by the user. A standard air bubble film machine can typically produce air bubble film at a speed ranging from a few meters per minute to several tens of meters per minute. This speed is determined by factors such as the width of the film, the size of the air bubbles, and the desired thickness of the film. Take Ztech’s standard bubble film making machine as an example. It can work 54kg/hr-180 kg/hr.

Are Air Bubble Film Machines Customizable to Specific Requirements?

Yes, air bubble film machines can be customizable to specific requirements. These machines are used for producing air bubble packaging material, commonly known as bubble wrap. They come in various sizes and configurations to cater to different production needs.

The customization options for air bubble film machines typically include:

●Film width: Machines can be designed to produce bubble wrap in different widths, ranging from small rolls to wider sheets.

●Bubble size: The size of the air bubbles can be adjusted based on specific requirements. Some machines offer the flexibility to produce various bubble sizes on the same machine.

●Film thickness: The thickness of the bubble wrap film can be customized to meet specific protective needs. Thicker films provide enhanced cushioning and protection.

Production speed: Machines can be designed to operate at different speeds to match the desired production volume and efficiency.

Can An Air Bubble Film Machine Produce Different Bubble Sizes and Configurations?

Absolutely, it can! The air bubble film machine is equipped with adjustable settings and interchangeable molds or rollers that allow for the production of bubble wrap with varying bubble sizes and configurations.

The process of producing different bubble sizes and configurations typically involves changing the molds or rollers within the machine. These molds or rollers have different patterns or designs that shape the bubble wrap as it is being manufactured. By replacing or adjusting these components, the machine can produce bubble wrap with bubbles of different sizes and configurations.

Can An Air Bubble Film Machine Handle Automated Packaging Processes?

Yes, an air bubble film machine can be integrated into automated packaging processes. These machines can be designed to work in conjunction with other packaging equipment, such as automated filling systems, sealing machines, or conveyor systems, to streamline the packaging process and improve efficiency.

Integration of an air bubble film machine into an automated packaging line typically involves:

●Conveyor systems

Air bubble film machines can be synchronized with conveyor systems to ensure a continuous flow of packaging materials. The bubble wrap produced by the machine can be automatically fed into the packaging line, allowing for seamless integration with other equipment.

●Sensor-based controls

Advanced air bubble film machines may feature sensor-based controls that enable them to communicate with other equipment in the packaging line. This facilitates coordination and synchronization between different machines, ensuring efficient operation and minimizing the need for manual intervention.

●Customized output

The air bubble film machine can be configured to produce bubble wrap in specific sizes, lengths, or quantities to align with the requirements of the automated packaging process. This ensures that the packaging materials are produced in a manner that optimizes the efficiency and effectiveness of the overall automated system.

Conclusion

Air bubble film machines are indispensable tools for modern packaging and shipping requirements. Their ability to produce protective air bubble wraps efficiently and cost-effectively makes them a valuable asset in various industries.