The PP Hollow Board Production Line is a cutting-edge manufacturing system that has transformed the packaging industry and found diverse applications in other sectors as well. This article explores this machine and illustrate its product ---- pp hollow board production line.

What is A PP Hollow Board Production Line?

A PP hollow board production line refers to a manufacturing system or equipment used to produce PP (polypropylene) hollow boards. It is a complete production setup that includes various machines and processes to fabricate these lightweight, durable, and versatile boards.

The PP hollow board production line is highly efficient and automated, allowing for continuous and large-scale production. It can produce PP hollow boards with various specifications, including different sizes, thicknesses, and colors. These boards find applications in industries such as packaging, advertising, construction, automotive, agriculture, and more.

What Are The Main Components Of A PP Hollow Board Production Line?

Generally speaking, due to different production needs and manufacturers, a pp hollow board production line can be various in the component. The main components of a PP hollow board production line typically include:

●Extruder

The extruder is a machine that melts the PP (polypropylene) resin and feeds it into the production line. It consists of a screw and barrel system that applies heat and pressure to melt and mix the raw material.

●Die

The die is a specialized tool or mold that shapes the molten PP material into a continuous flat sheet with hollow structures. It determines the size, thickness, and pattern of the hollow boards.

●Cooling System

After passing through the die, the hot PP sheet needs to be rapidly cooled to solidify and stabilize it. The cooling system typically uses air or water cooling methods to achieve this.

●Haul-off Machine

The haul-off machine pulls the cooled PP sheet forward at a controlled speed. It ensures the smooth and consistent movement of the sheet through the production line, preventing any deformation or damage.

●Cutting Machine

The cutting machine is responsible for cutting the continuous PP sheet into individual boards of desired lengths. It can employ various cutting methods such as knife cutting, saw cutting, or laser cutting, depending on the specific production requirements.

●Stacking System

The stacking system collects the cut PP boards and stacks them in an organized manner. It may include conveyors, robotic arms, or other mechanisms to handle and arrange the boards for packaging or further processing.

●Control System

The control system consists of electronic controls, sensors, and human-machine interfaces (HMIs) that manage and monitor the production line's operation. It enables operators to adjust and control various parameters such as temperature, speed, and dimensions to ensure accurate and efficient production.

●Auxiliary Equipment

Additional auxiliary equipment may be included in a PP hollow board production line, depending on specific requirements. This can include equipment for material feeding, drying, printing, surface treatment, and edge trimming.

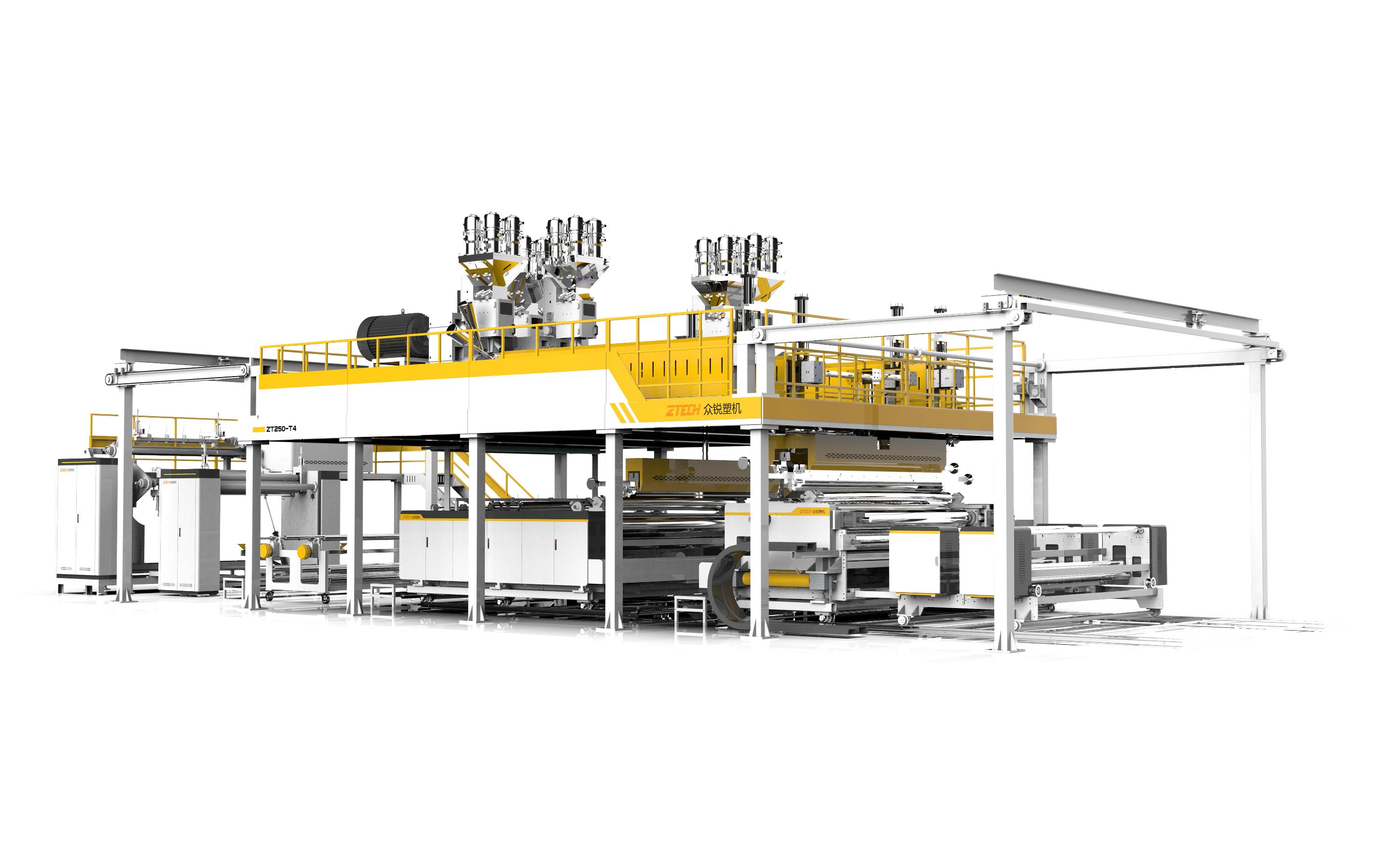

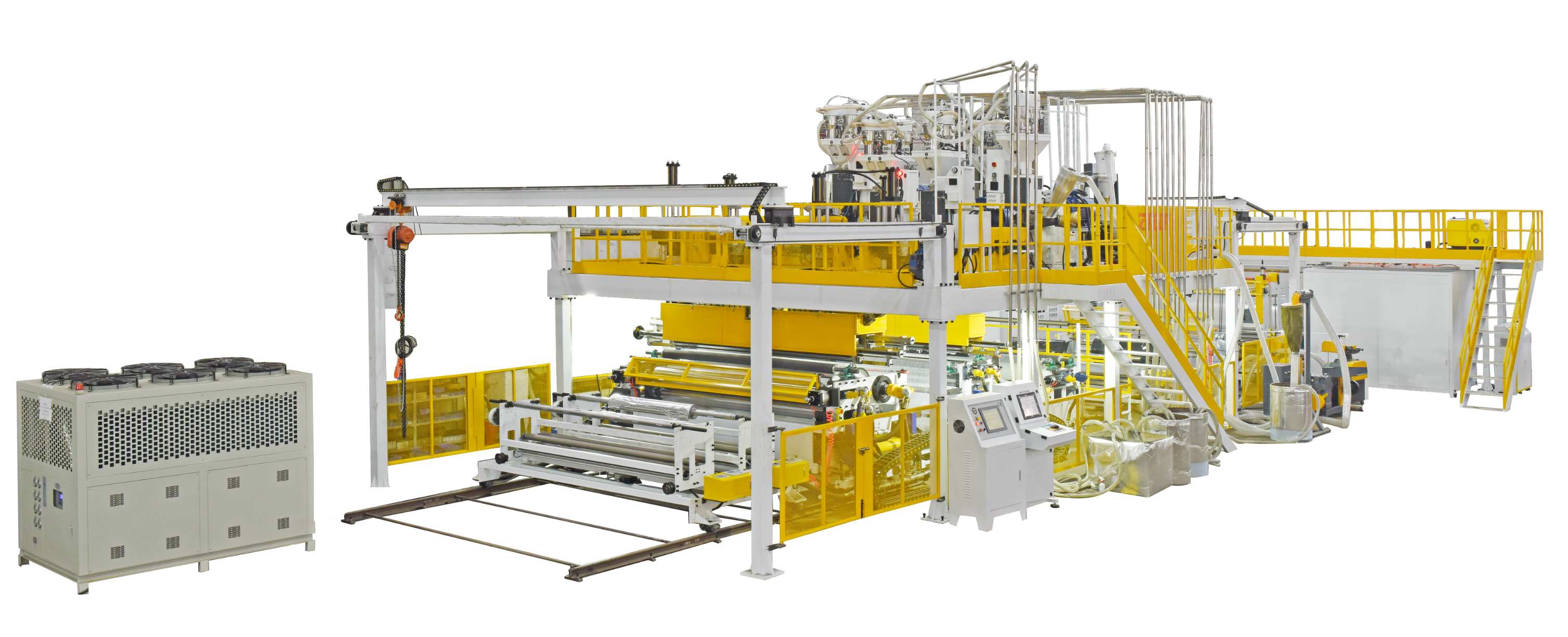

PP Hollow Board Production Line

What Are the Features of the PP Hollow Board Production Line?

In Ztech, our PP hollow board production line has the following features:

●Optimized screws and groove design barrel

The production line is equipped with screws and a barrel that have been optimized for performance. This design ensures high plasticization of the raw material and even melting, resulting in a stable and consistent production process.

●High plasticization

The extruder in the production line is capable of achieving a high level of plasticization, which means that the raw material is thoroughly melted and mixed to form a homogenous molten mass.

●Stable and consistent production

The combination of optimized screws, groove design barrel, and high plasticization ensures stable and consistent production of PP hollow boards. This means that the produced boards will have uniform properties and meet the required specifications.

●High-performance reducer

The production line is equipped with a high-performance reducer, specifically the Guomao reducer. This gear reducer offers high torque, which is crucial for driving the extruder and other components of the production line. Additionally, it has a long service life and operates with low noise, ensuring reliable and efficient performance.

●AC drive motor

The production line utilizes an AC drive motor, which offers several advantages. AC motors are known for their high efficiency, reliability, and precise control. They can provide the required power and speed control for the extruder and other components of the production line.

What is PP Hollow?

PP Hollow boards are made from polypropylene, a thermoplastic polymer known for its excellent properties such as high impact resistance, chemical resistance, and durability. The boards are manufactured through a process called extrusion, where molten polypropylene is forced through a die to form a hollow structure with a series of parallel ridges on the surfaces.

The hollow structure of PP Hollow boards provides them with several advantageous features. They have a high strength-to-weight ratio, making them lightweight yet strong. The hollow cells also add rigidity to the boards, making them resistant to bending and warping. Additionally, the hollow design allows for better insulation, making PP Hollow boards suitable for applications requiring thermal or sound insulation properties.

What is the Use of PP Hollow Sheet?

PP Hollow Sheets, also known as Polypropylene Hollow Sheets or Polypropylene Hollow Boards, have various uses and applications across different industries. Some of the common uses of PP Hollow Sheets include:

●Packaging

PP Hollow Sheets are widely used in the packaging industry for creating boxes, crates, dividers, and trays. They provide lightweight yet durable protection for various products during storage and transportation. The sheets can be easily cut, folded, and fabricated to meet specific packaging requirements.

●Advertising and Display

PP Hollow Sheets are popular in the advertising and display industry due to their lightweight nature, printable surfaces, and weather resistance. They are used to create signage, display boards, exhibition panels, and promotional materials. The sheets can be easily printed, laminated, and shaped to showcase advertising messages and graphics.

●Construction and Building

PP Hollow Sheets find applications in the construction industry as well. They are used for temporary walls, partitions, and barriers during construction projects. The sheets can be easily assembled and disassembled, providing flexibility and cost-effectiveness. Additionally, they are used as formwork for casting concrete structures and as protective coverings during renovation or painting works.

●Automotive Industry

PP Hollow Sheets are used in the automotive industry for various applications such as interior trims, door panels, and packaging for automotive components. The sheets offer lightweight solutions while providing strength and durability.

●Agriculture and Horticulture

PP Hollow Sheets are used in agriculture and horticulture for applications such as greenhouse roofing, plant protection, and temporary fencing. The sheets provide protection from UV rays, weather elements, and pests, while allowing light transmission and airflow.

●Signage and Displays

PP Hollow Sheets are commonly used for creating signs, banners, and displays in retail stores, events, and exhibitions. Their lightweight and rigid nature make them easy to install, transport, and reuse.

●Stationery and Crafts

PP Hollow Sheets are also used for various stationery and craft purposes. They can be used to create folders, binders, document holders, and DIY craft projects due to their versatility and ease of cutting and shaping.

Conclusion

The PP Hollow Board Production Line has revolutionized the manufacturing of PP Hollow Sheets, enabling the production of lightweight, durable, and versatile material used in various industries. Its optimized design, high-performance components, and exceptional features make it an indispensable tool for the production of PP Hollow Sheets, catering to diverse applications from packaging to advertising, construction to automotive, and beyond.