Plastic recycling plays a vital role in mitigating environmental issues and reducing waste. Among the essential tools in the recycling process is the plastic recycling extruder machine.

To ensure the smooth and efficient operation of these machines, regular maintenance is crucial. In this article, we will explore the necessary steps to maintain plastic recycling extruder machines effectively.

What are Plastic Recycling Extruder Machines?

Plastic recycling extruder machines are key components of the recycling process. They transform recycled plastic materials into new usable products.

These machines consist of several essential parts, including the hopper, barrel, screw, heating elements, and die. Different types of extruder machines are used in the industry, each catering to specific recycling needs.

What is the Importance of Regular Maintenance?

Maintaining plastic recycling extruder machines is not just a matter of good practice; it is essential for several reasons. Regular maintenance ensures consistent output quality and prevents unexpected breakdowns, reducing downtime and operating costs. Neglecting maintenance can lead to decreased efficiency and even permanent damage to the machine.

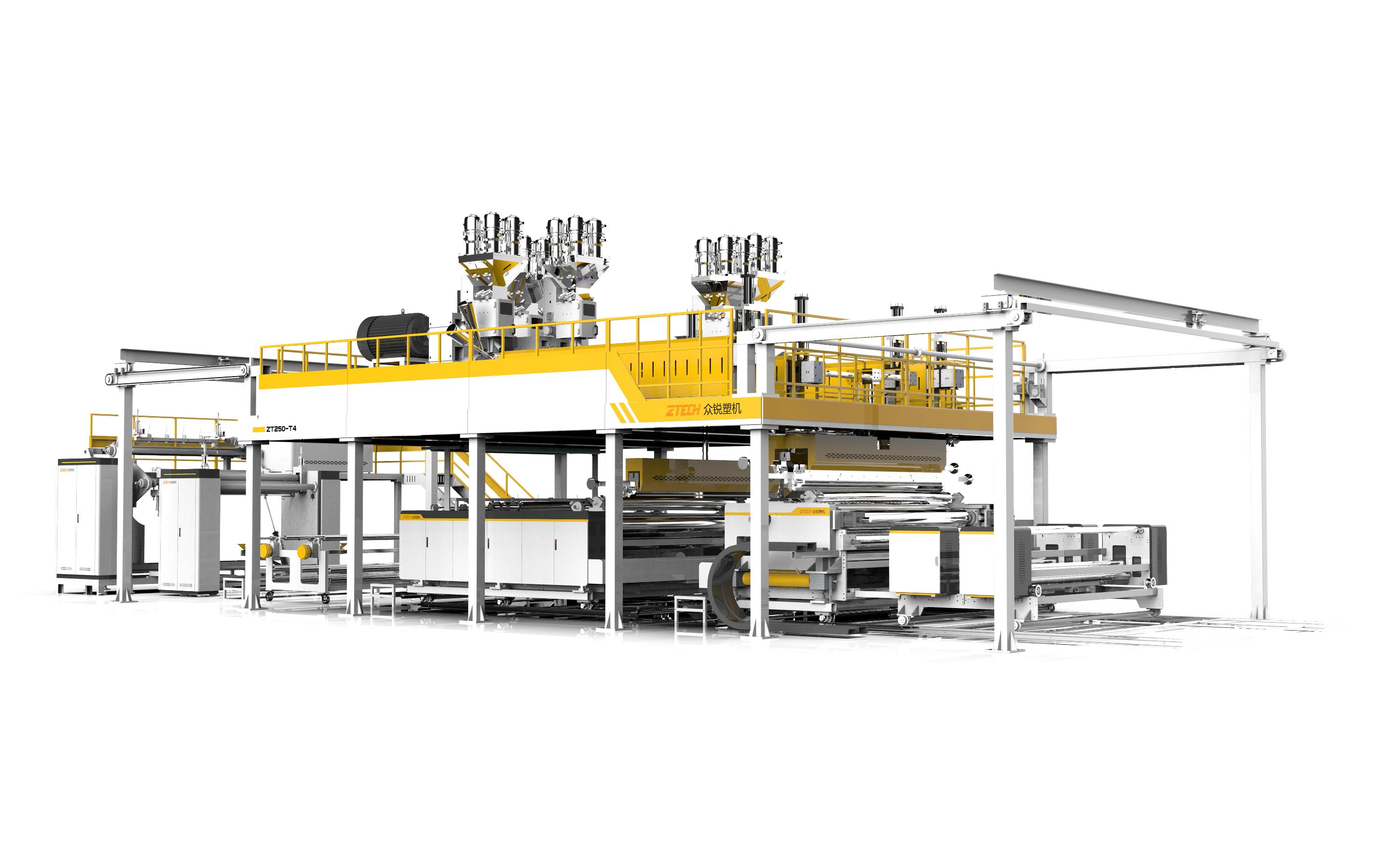

Plastic Recycling Machine China

How to Make Maintenance Schedule and Checklist?

To facilitate effective maintenance, a well-structured maintenance schedule is required. Consider factors like the frequency of machine usage and the manufacturer's recommendations when creating a schedule. Below is a sample maintenance schedule template:

| Maintenance Task | Frequency |

| Daily Tasks | Daily |

| Weekly Tasks | Weekly |

| Monthly Tasks | Monthly |

| Annual Tasks | Annually |

Daily Maintenance Tasks

Daily maintenance tasks are essential for keeping the extruder machine in optimal condition. Some of these tasks include:

●Cleaning the Hopper: Remove any remaining plastic residues from the hopper to prevent contamination of the next batch.

●Inspecting the Barrel and Screw: Check for signs of wear and tear, and clean them if necessary.

●Checking for Leaks: Examine the machine for any signs of leaks in the hydraulic or pneumatic systems.

Weekly Maintenance Tasks

On a weekly basis, focus on more in-depth maintenance activities, such as:

●Checking and Replacing Worn Parts: Inspect parts like bearings, seals, and belts for signs of wear and replace them as needed.

●Inspecting the Gearbox: Ensure that the gearbox is properly lubricated and functioning smoothly.

●Lubricating Components: Apply appropriate lubricants to the required parts.

Monthly Maintenance Tasks

Monthly maintenance tasks cover comprehensive aspects of the machine, including:

●Inspecting Electrical Components: Check electrical connections and components for any signs of damage or overheating.

●Verifying Temperature Accuracy: Ensure that the heating elements are maintaining the required temperatures accurately.

●Cleaning the Cooling System: Clean the cooling system to prevent overheating during operation.

Annual Maintenance Tasks

Annually, carry out more extensive maintenance tasks to keep the extruder machine in top condition:

●Complete Barrel and Screw Inspection: Thoroughly inspect the barrel and screw for wear and potential damage, considering replacements if necessary.

●Gearbox Servicing: Perform a full service on the gearbox, including lubrication and checking for any internal issues.

Overall Performance Evaluation: Evaluate the machine's overall performance and make necessary adjustments for optimal operation.

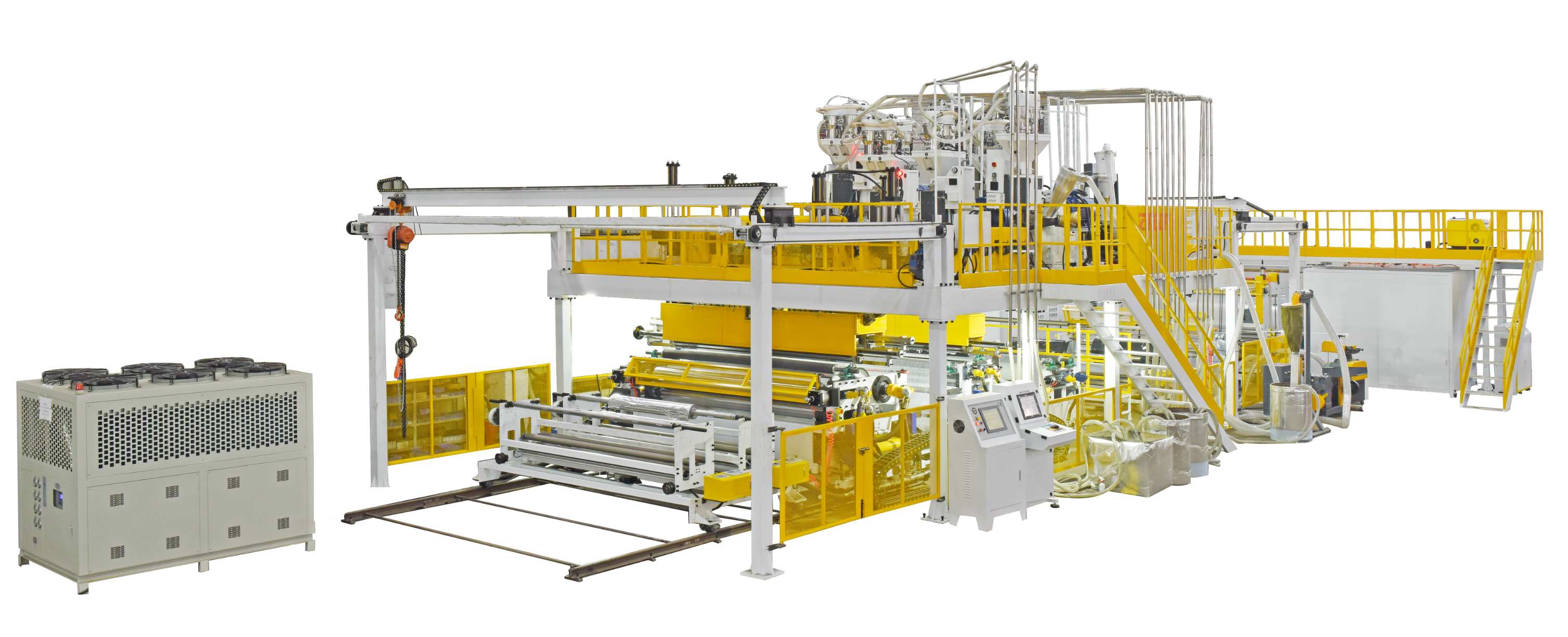

Water Ring Plastic Recycling Machine

How to Clean and Lubricate the Plastic Recycling Extruder Machines?

In this section, the author would gudie you how to clean and lubricate the plastic extruder machines.

●Importance of Cleaning

Cleaning the extruder machine is a crucial aspect of maintenance. Proper cleaning prevents material build-up, contamination, and potential damage to components.

●Cleaning Procedure

Follow these steps to clean the extruder machine effectively:

Shut Down and Disconnect: Before cleaning, ensure the machine is powered off and disconnected from the power source.

Disassemble Components: Carefully disassemble relevant parts, such as the hopper, barrel, and screw.

Use Appropriate Cleaning Agents: Utilize suitable cleaning agents to remove any plastic residues and contaminants.

Inspect and Clean Cooling System: Check the cooling system for debris or blockages, and clean it thoroughly.

Reassemble the Machine: After cleaning, reassemble the machine components properly.

Lubrication Guidelines

Proper lubrication reduces friction and wear within the machine, contributing to its overall efficiency and lifespan. Follow these lubrication guidelines:

Choose the Right Lubricants: Use lubricants recommended by the machine's manufacturer for each specific component.

Regular Lubrication: Follow the maintenance schedule to ensure regular lubrication of relevant parts.

Avoid Over-Lubrication: Do not over-lubricate, as it may attract dust and debris, leading to potential issues.

Conclusion

Maintaining plastic recycling extruder machines is crucial for efficient and sustainable recycling operations. Regular maintenance, including cleaning, lubrication, and adherence to a maintenance schedule, ensures consistent output quality and prolongs the machine's lifespan.

By following these maintenance guidelines, recycling facilities can contribute to a cleaner environment while maximizing the efficiency and effectiveness of their extruder machines.