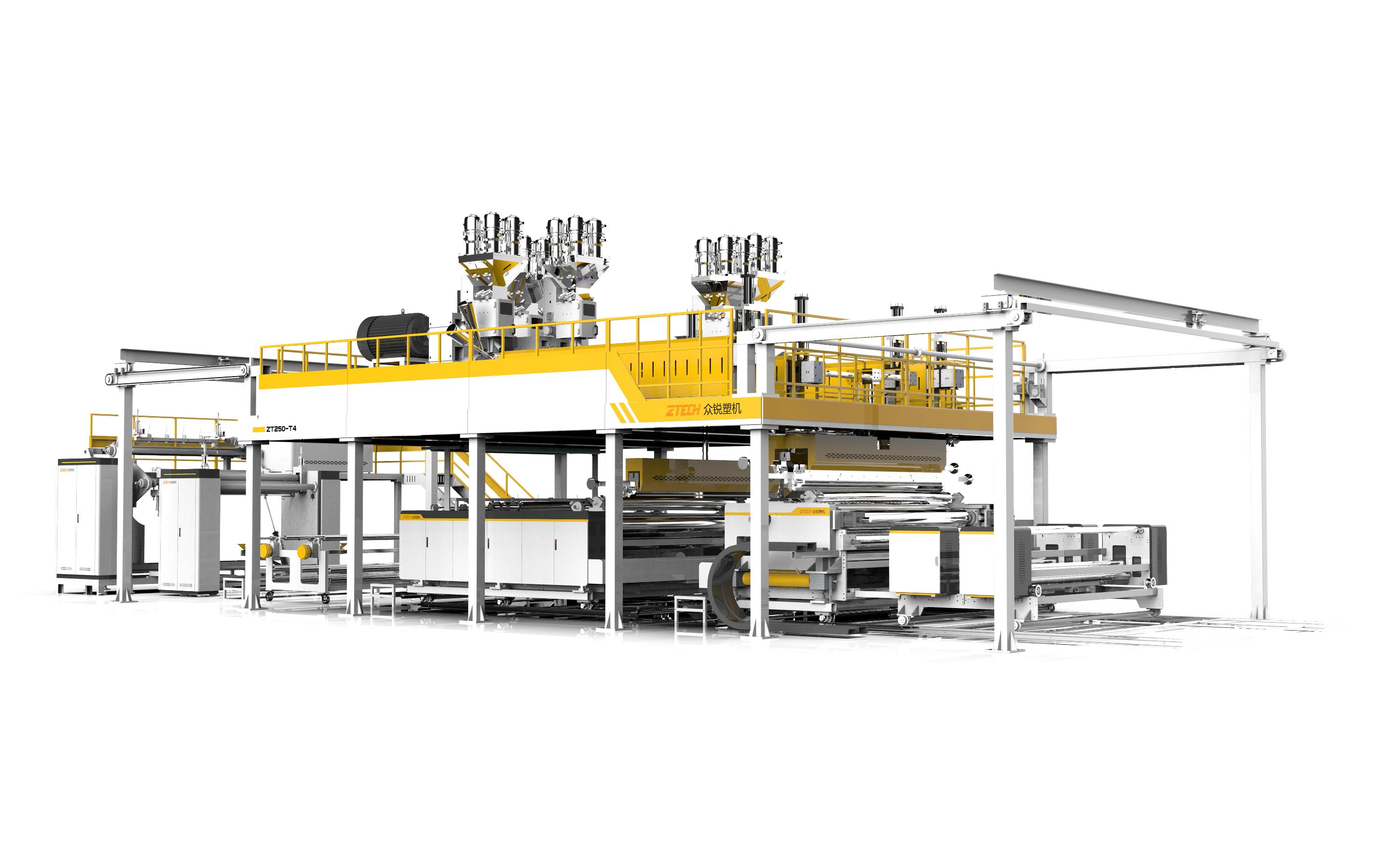

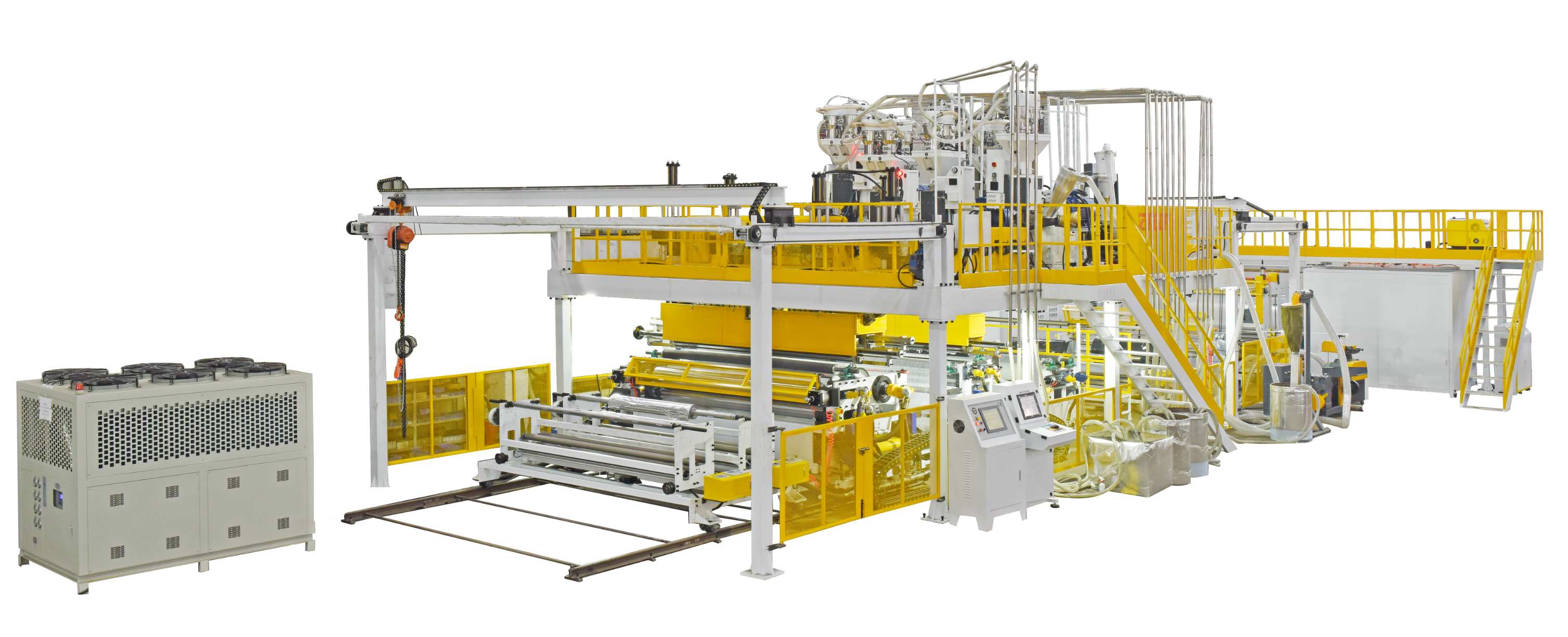

In the field of bubble film production, the performance of the air bubble film extrusion directly determines the production efficiency and product quality. As a leading enterprise in the industry, ZTECH has established industry benchmarks with "technological leadership, energy efficiency, and customized services" through continuous deep cultivation and innovation in air bubble film extrusion technology. It provides global customers with full-chain support from equipment to solutions, fully demonstrating its strong corporate strength.

The reason why ZTECH's air bubble film extrusion can stand out in the market lies in its industry-leading core technologies. As the enterprise that first launched a number of innovative models such as nylon co-extrusion air bubble film extrusion and ABA co-extrusion air bubble film extrusion in China, ZTECH's R&D team has always been at the forefront of technology, and its cutting-edge design ideas have been followed and learned by peers. Many core technical highlights can be seen in each air bubble film extrusion: the full-touch temperature control system can monitor temperature and speed in real time, and the intelligent fault prompt improves operation and maintenance efficiency by 30%; the automatic thickness control system accurately controls the weight, with an error within 3g, greatly reducing raw material waste; the original embossing roller design adopts water circulation cooling, ensuring full bubbles during high-speed production, and at the same time, the durability of the air bubble film extrusion is increased by 10 times; the die head uses professional mold steel and a two-way adjustment structure, making the bubble film produced from the same raw material stronger and more uniform in thickness. It is particularly worth noting that ZTECH is the only manufacturer in China that can achieve stable production at 100 meters per minute. Its air bubble film extrusion's high-speed performance far exceeds the industry standard of 30 meters and can run for a long time. This technical advantage has attracted many customers.

The energy-saving solution of ZTECH's air bubble film extrusion provides strong support for customers to reduce costs and increase efficiency. Through the unique screw design, ZTECH's air bubble film extrusion can use 100% recycled materials. The products produced under the same raw materials are lighter and thinner, and the raw material cost is reduced by 15%-20%; automatic winding, thickness control and other systems reduce manual intervention, saving 30% of labor costs; the intelligent adjustment function when starting up and changing formulas reduces the scrap rate to less than 1%. From raw material utilization to production process, the entire chain achieves "less waste and high efficiency".

The choice of many customers has confirmed the value of ZTECH's air bubble film extrusion. After a large domestic packaging enterprise introduced a customized 80-meter/minute air bubble film extrusion, combined with automatic thickness control and recycled material technology, not only the production capacity doubled, but also the annual raw material cost was reduced by nearly one million yuan; the air bubble film extrusion exported to Germany, with CE certification and stable high-speed performance, helped local manufacturers quickly seize the high-end packaging market. Today, ZTECH's air bubble film extrusion has spread to many countries such as the United States, the United Kingdom, and Spain, interpreting the true meaning of "customized production" with technology and services.

ZTECH has always focused on customers' personalized needs, and deeply integrated cutting-edge technological innovation and the concept of full-process energy conservation into the design and manufacturing of each air bubble film extrusion. By transforming its technical advantages in high-speed and stable production, precise control, and efficient use of raw materials into customers' production competitiveness in terms of production capacity improvement, cost reduction, and product quality optimization, ZTECH's air bubble film extrusion continues to promote the bubble film industry to upgrade towards high efficiency, environmental protection, and intelligence, and has become the core driving force leading the industry's progress.